Shear stress

|

|

|

| SI symbol: | τ |

| SI unit: | pascal |

| Derivations from other quantities: | τ = F / A |

is applied to the top of the square while the bottom is held in place. This stress results in a strain, or deformation, changing the square into a parallelogram.

is applied to the top of the square while the bottom is held in place. This stress results in a strain, or deformation, changing the square into a parallelogram.A shear stress, denoted  (tau), is defined as a stress which is applied parallel or tangential to a face of a material, as opposed to a normal stress which is applied perpendicularly.

(tau), is defined as a stress which is applied parallel or tangential to a face of a material, as opposed to a normal stress which is applied perpendicularly.

Contents |

General shear stress

The formula to calculate average shear stress is:

where

= the shear stress

= the shear stress- F = the force applied

- A = the cross sectional area

Other forms of shear stress

Beam shear

Beam shear is defined as the internal shear stress of a beam caused by the shear force applied to the beam.

where

- V = total shear force at the location in question

- Q = statical moment of area

- t = thickness in the material perpendicular to the shear

- I = Moment of Inertia of the entire cross sectional area

This formula is also known as the Jourawski formula.[1]

Semi-monocoque shear

Shear stresses within a semi-monocoque structure may be calculated by idealizing the cross-section of the structure into a set of stringers (carrying only axial loads) and webs (carrying only shear flows). Dividing the shear flow by the thickness of a given portion of the semi-monocoque structure yields the shear stress. Thus, the maximum shear stress will occur either in the web of maximum shear flow or minimum thickness.

Also constructions in soil can fail due to shear; e.g., the weight of an earth-filled dam or dike may cause the subsoil to collapse, like a small landslide.

Impact shear

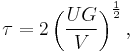

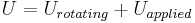

The maximum shear stress created in a solid round bar subject to impact is given as the equation:

where

- U = Change in Kinetic Energy

- G = Shear Modulus

- V = Volume of Rod

and

= Mass Moment of Inertia

= Mass Moment of Inertia = Angular Speed

= Angular Speed

Shear stress in fluids

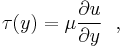

Any real fluid (liquids and gases included) moving along solid boundary will incur a shear stress on that boundary. The no-slip condition[2] dictates that the speed of the fluid at the boundary (relative to the boundary) is zero, but at some height from the boundary the flow speed must equal that of the fluid. The region between these two points is aptly named the boundary layer. For all Newtonian fluids in laminar flow the shear stress is proportional to the strain rate in the fluid where the viscosity is the constant of proportionality. However for Non Newtonian fluids, this is no longer the case as for these fluids the viscosity is not constant. The shear stress is imparted onto the boundary as a result of this loss of velocity. The shear stress, for a Newtonian fluid, at a surface element parallel to a flat plate, at the point y, is given by:

where

is the dynamic viscosity of the fluid,

is the dynamic viscosity of the fluid, is the velocity of the fluid along the boundary, and

is the velocity of the fluid along the boundary, and is the height of the boundary.

is the height of the boundary.

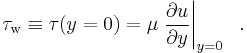

Specifically, the wall shear stress is defined as:

In case of wind, the shear stress at the boundary is called wind stress.

Diverging fringe shear stress sensor

This relationship can be exploited to measure the wall shear stress. If a sensor could directly measure the gradient of the velocity profile at the wall, then multiplying by the dynamic viscosity would yield the shear stress. Such a sensor was demonstrated by A. A. Naqwi and W. C. Reynolds[3]. The interference pattern generated by sending a beam of light through two parallel slits forms a network of linearly diverging fringes that seem to originate from the plane of the two slits (see double-slit experiment). As a particle in a fluid passes through the fringes, a receiver detects the reflection of the fringe pattern. The signal can be processed, and knowing the fringe angle, the height and velocity of the particle can be extrapolated.

See also

- Direct shear test

- Shear modulus

- Shear rate

- Shear strain

- Shear strength

- Shear and moment diagrams

- Stress (physics)

- Tensile stress

- Triaxial shear test

References

- ↑ Timoshenko, Stephen P. (1983), History of Strength of Material, Courier Dover Publications, p. 141, ISBN 0486611876, http://books.google.com/books?id=tkScQmyhsb8C.

- ↑ Day, Michael A. (2004), The no-slip condition of fluid dynamics, Springer Netherlands, pp. 285–296, ISSN (Print) 1572-8420 (Online) 0165-0106 (Print) 1572-8420 (Online), http://www.springerlink.com/content/k1m4t1p02m778u88/.

- ↑ Naqwi, A. A.; Reynolds, W. C. (jan 1987), "Dual cylindrical wave laser-Doppler method for measurement of skin friction in fluid flow", NASA STI/Recon Technical Report N 87

External links

- The second page of this brochure explains the concept of the diverging fringe shear stress sensor mentioned above.